used

It can be used for cutting of metal

High power and high quality of laser output

The electro-optical conversion efficiency is high, the spot energy distribution is flat top, and the energy density is high.

Compact structure and smaller size

Built-in single module integration of high power;smaller machine size

Excellent performance and low processing cost

It can be used for cutting of metal

Anti-height reflex

With unique and innovative hardware-grade anti-high reflection protection technology, it can process a variety of high reflection materials.

Modular design and easy maintenance

Adopt photoelectric module separation design, which has stable operation and less failure, and is more convenient for later maintenance.

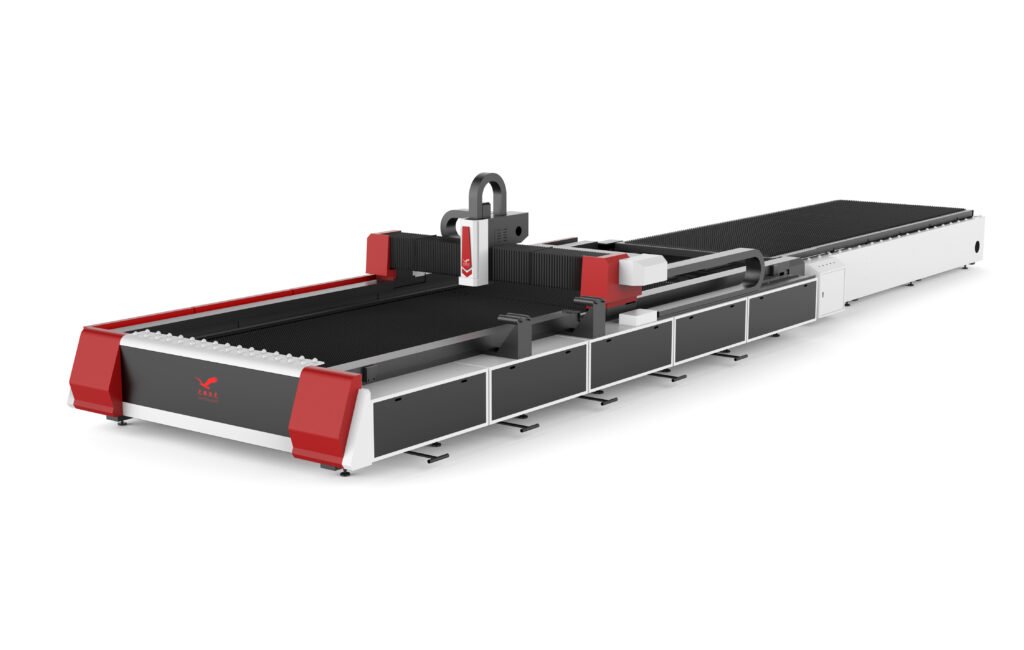

Brief Introduction to the Double Worktable Laser Cutting Machine

It features two worktables, A and B, which can move back and forth. While worktable A is actively performing automatic cutting, worktable B can simultaneously handle the loading of metal sheets and the unloading of cut materials.

This design significantly enhances cutting efficiency, improves factory operational performance, and generates higher profits!

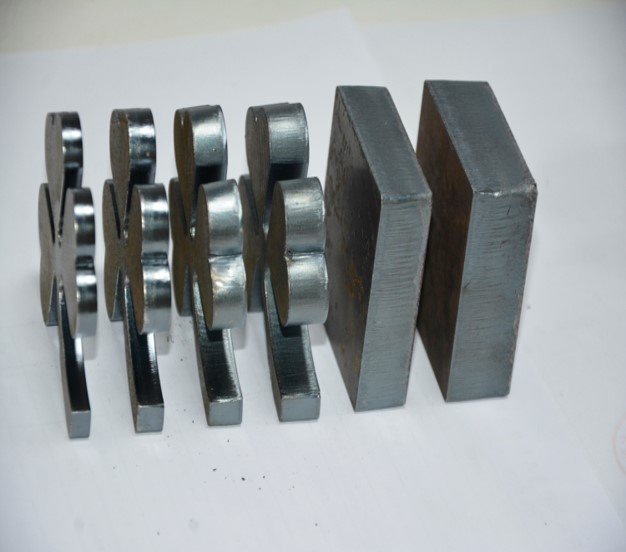

Cutting product display

Characteristics of laser cutting

a.The characteristics of laser cutting machine:Narrow slit, small deformation, high precision, fast speed and high efficiency.

b.Laser light energy is converted into amazing heat energy which can keep in a very small area,so laser cutting can provide: narrow straight edge slit,the smallest heat-affected zone near the cutting edge,and tiny local deformation.

c.The laser beam does not exert any force on the workpiece,and it is a non-contact cutting tool,which means that there is no mechanical deformation to the workpiece,no deformation of cutting tool and no replacement demand of cutting tool.It doesn’t need to consider the hardness of the material while cutting,so,that is to say,the ability of laser cutting is not affected by the hardness of the material.

d.The laser beam is highly controllable and has high adaptability and flexibility,making it easy to realize the automatic production of cutting.

The preferred reason for purchasing a machine

a.Designed for export, for customers to save transportation costs, the overall width of the cutting machine is in accordance with the size of the container from the main design, and the width is 2.25 M.It can go straight into the cabinet without removing the sheet metal.

b.According to the voltage requirements of different countries, the corresponding machine accessories can be adapted.

c.The bed is welded as a whole,and processed after annealing to eliminate the internal stress.The process is welding→annealing to eliminate the internal stress→roughing process→vibration aging→finishing process,which better solves the stress caused by welding and processing,thus greatly improving the stability of the machine bed and maintaining the accuracy of the bed for a long time. The company has gantry processing department and machining processing department,which are mainly for the production of all the company's complete sets of machine bed,beam,base and other machine parts.Distinguished from other laser integration manufacturers, all the structural parts of our company are independently processed by us and without any other external producing products.The processing quality is consistent with the product quality,the production period of the equipment is guaranteed,and it is linked with the final quality of the product, so that the quality of each laser product is consistent.

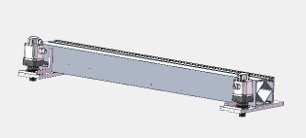

The beam adopts tensile aluminum welded integrated beam, which has good rigidity and light weight, and reduces the cumulative error generated in the assembly process of traditional beam.It also has good structural strength which can withstand the inertia generated by greater accelerated speed, ensuring that the cutting accuracy is more stable. The beam is double drive structure on the left and right;The beam is integrally welded to reduce the error caused by high-speed operation. The reducer uses TDP090 series integrated flange output of German brand TECHMECH.The speed ratio is 5, and the back gap is within 3 arc minutes; M2 oblique teeth, 6-level precision and 22-tooth gear provide greater torque. Servo motor is YASKAWA bus control, with power 1.8 KW, high inertia, rated speed 1500 r/min, and the maximum speed 3000 r/min. Top of beam + double guide rail and four sliders on the side + single rack drive structure. The protective cover is fully enclosed light fire and oil resistant type.Both ends have anti-collision glue,providing overshoot protection.

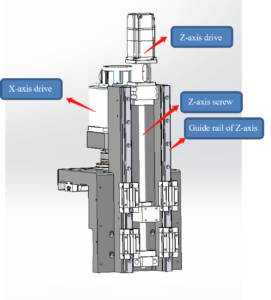

It adopts cast aluminum structure and is cast in one body. It has stable structure and light weight. The Z-axis has two parts:one is the overall Z-axis movement, and the other is the up and down movement of cutting head. Z-axis drive:The reducer uses TDP090 series integrated flange output of German brand TECHMECH.The speed ratio is 5, and the back gap is within 3 arc minutes; Use M2 oblique teeth of 6-level precision;Servo motor is YASKAWA bus control, with power 0.85 KW, maximum speed 3000 r/min and high inertia. Cutting head drive:Adopts double guide screw drive. Servo motor is YASKAWA bus control series, with its power 400 W and maximum speed 6500 r/min, and it is medium inertia type.The guide rail uses GHHR20 series of HIWIN brand, and class H (advanced) precision of heavy load type. The screw uses R15-10K3-FSC series of HIWIN brand.There is limited position switch at both ends of the overshoot protection stroke to control the stroke and elastic cushion supplemented on both sides to effectively ensure the safety of cutting head movement.

There is a special optimization and upgrading for specific use environments to achieve long-term reliable and stable operation in daily industrial environments.Adopts ultra-precision and ultra-smooth lens processing technology, with excellent cutting quality and speed; Achieve seamless connection and deep integration with the system to further improve production and processing efficiency; With module component design and on-site rapid maintenance of equipment, customers can quickly restore production capacity to achieve 24 hours of uninterrupted production. Further reduce users’ costs with localization service and maintenance.

Characteristics of product :

a.The internal structure of the laser head is completely sealed, which can avoid contamination of the optical lens.

b.The laser head adopts two-point alignment adjustment, and the focusing mechanism is driven by servo motor, which can significantly improve the perforation efficiency.

c.The protective mirror structure adopts drawer type, which is easy to replace.

d.It can be used for all kinds of lasers with QBH fiber connectors.

Parameters of product:

| Maximum air pressure | 25 Bar | Horizontal focusing range | ±1.5 mm | Effective light aperture | 25 mm |

| Collimating focal length | F150-F200 | Vertical focusing range | ±8 mm | Weight | 5.5 kg |

| Focal length | F150/F200 | Applicable power | ≤8000 W | Fiber interface | QBH、EOC |

The requirements of the equipment on the site environment

| NO. | Items | Requirement |

| 1 | Power source | Three phase 380V±5% 50Hz |

| 2 | Compressed air | Dry filtered air 1.3Mpa-1.6Mpa |

| 3 | Working environment | Air circulation, no dust and no oil mist |

| 4 | Environment temperature | 20±2°-30±2° |

| 5 | Ground requirement | Continuous flat dry concrete floor, with thickness ≥20 cm. Flatness 8 mm/ full length |

The power cable is single 6 mm² or above, and the air switch is 100 A or above.Prepare an independent grounding protection on site, drive the ground pile at least 1.5m deep into the ground, and pour salt water around it for grounding protection. Do not share ground cables with other devices.

To use air,prepare air compressor + cold dryer + oil-water separator, and the constant pressure of air should reach 1.35 Mpa and achieve no water and no oil to meet the production. If the pipeline and lens damage are due to unclean air filtration,it is not covered by the warranty.

The cold dryer and air compressor can be placed outdoors, and the surrounding environment must be dry, less dust, rainproof, etc., and the single connection pipe between the chiller and the laser cannot exceed 10 M.

Chillers, air compressors and freeze dryers placed indoors must be dust free and well ventilated; cooling water requirements.

If it cannot be replaced by barreled pure water, deionized water or distilled water must be used, but mineral water cannot be used, otherwise it will affect the service life of the laser.

In frozen areas in winter, the chiller must be placed in an environment above 0 ° C, and if it is below 0 ° C, antifreeze must be added.

Environmental conditions of use

a.Power supply specification: 380V, 50Hz, and stable voltage.

b.Grounding protection: Ground the machine by driving pile grounding wire on the machine side, and you can also connect the machine to the ground wire of the power supply.The grounding resistance is required to be <4Ω.

c.External air source: Composed of air compressor, air storage tank, refrigerated compressed air dryer and compressed air precision filter.The following is the complete set of parameters of the air source recommendations:

| Screw air compressor | Air holder | ||

| Power:22.3 KW | Volume flow:1.2 m³/min | Volume:0.6 m3 | Design pressure:1.6 Mpa |

| Voltage:380 V | Working pressure:1.6 Mpa | ||

| Refrigerated compressed air dryer | Compressed air precision filter | ||

| Refrigerant:R22 | Pressure of use:1.6 Mpa | Grade: AA | Working pressure:≤1.6 Mpa |

| Treated air volume:2.6 m³/min | Impurity size:0.01 μm | Residual oil:0.001 ppm | |

The air compressor can be placed outdoors, but it should be within 10 meters from the pipe cutting machine to ensure a stable air supply. d.Site requirements: There must be no major vibration around the installation foundation. e.Function of chiller: It is used for cooling laser, cutting head, QBH and other special equipment, and cooling circulating water requires the use of high-quality pure water or distilled water; f.Reserve space: The distance between the back and tail of the machine tool and the workshop wall should be more than 1.0 meters. g.Environmental requirements: The control unit, servo unit and display and control panel are the core parts of the machine tool, which have certain requirements for the environment, and should avoid the interference of the machine tool by electromagnetic waves, such as arc welding and discharge processing machines, so as to affect the normal operation of the machine tool.

After-sales service

1.After the acceptance of the equipment,the quality guarantee period of the machine is one year.The system has included a one-year service and parts warranty period.If there is a quality problem with the system parts during the warranty period,our well-trained service engineers will provide telephone or on-site service at any time.

2.During the warranty period,our company is responsible for parts replacement and services free of charge due to any damage caused by the the quality of the equipment itself, but except for general consumables (such as optical lens and cutting nozzle) and accidents which belong to user’s responsibility for faulty operation.

3.After the installation, debugging and acceptance of the equipment are completed,our company can send a technician to guide the user on site for 1 month(the user privide food,room and salary ) to help the user solve the problems that may be encountered during the initial use of the equipment.

4.Our company provides life-long maintenance service to the product we provide, and provides daily consultation and instruction at any time. In addition to the warranty period,our company still provides extensive and preferential technical support and spare parts supply for the customer.

5.Our company is free for customers to reserve technicians of operation and maintenance for a long term who are high-quality and strictly trained through our company and are always ready to serve customers, which solves the trouble of customers looking for technical personnel.

6.After the equipment leaves the factory, our company will establish a "user file card" to track and record the relevant information of the user using the equipment.After the equipment maintenance service is completed, our company will report the cause of failure, remedial measures,the time and date of finishing the maintenance and returning to normal to customer.And the report is in duplicate for future reference.

7.Our company promises to inform the buyer of the software upgrade situation in time, and provide software upgrade services free of charge.

8.Our company has sufficient spare parts and accessories, and can provide technical services and spare parts services to customers in time to meet the needs of equipment maintenance.

9.Our company regularly arranges project engineers to the user site for free technical return visit services.

Every inquiry marks the beginning of our service.

Thank you for your patient attention.