Working Principle of the Equipment

Laser welding utilizes a high-energy-density laser beam as a heat source, which is focused through an optical system into a very small area. In an extremely short time, this creates a highly concentrated heat source zone at the welding spot, causing the material to melt and form a strong weld point or seam. The smaller the focused laser spot, the higher the power density at the focal point, leading to greater welding efficiency for the same weld depth requirement. Similarly, for the same welding efficiency requirement, the weld depth achieved is greater. Laser welding involves using high-energy laser pulses to locally heat a small area of the material. The energy from the laser radiation diffuses into the material through heat conduction, melting it to form a specific molten pool.

Processing Range of the Equipment

This equipment can weld metals such as copper, aluminum, iron, stainless steel, etc. The thickness range for welding is 0.5mm to 6mm.

Advantages of the Equipment

It is a new type of welding method. It offers a high depth-to-width ratio, narrow weld seams, a small heat-affected zone, minimal deformation, and fast welding speeds. The welds are smooth and aesthetically pleasing, requiring no post-weld treatment or only simple processing. It can perform spot welding, butt welding, lap welding, seal welding, and more. The fully automated laser welding system, combined with a fully automated wire-feeding system, enhances efficiency. Thanks to the intelligent design of the equipment, personnel with minimal training can operate it and achieve results comparable to those of traditional professional welding engineers. In essence, the equipment itself is like a highly experienced welding engineer.

Economic Benefits of the Equipment

No professional welding engineers are required; any worker of legal working age can achieve ideal welding results after simple training. The equipment consumes only a small amount of gas during operation (we generally recommend using argon), with an hourly power consumption of approximately 4-5 kW. Additionally, its welding speed is 5-10 times faster than traditional welding (based on straight-line welding test data).

Differentiated Services

We meticulously segment the market, carefully design solutions, and continuously introduce a variety of laser products tailored to customer needs, providing customized services for our clients.

What We Want to Say

In today's increasingly competitive market, we not only strive for precision, high quality, and efficiency in our products but also aim to provide meticulous, attentive, and dedicated service.

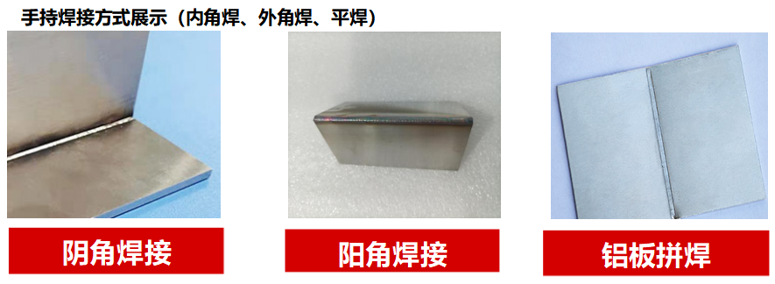

Handheld Laser Welding Machine

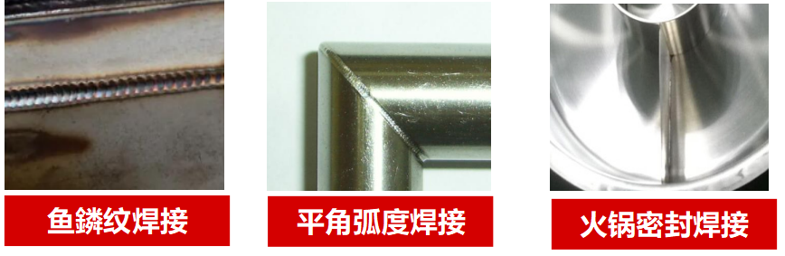

Sample Display of Equipment Welding

Comparison of Weldable Materials, Thicknesses, and Equipment Power

1500W Power Equipment Weldable Thickness

- Stainless Steel: 0.5mm–3mm

- Aluminum Alloy: 1mm–2.5mm

- Carbon Steel (Iron): 0.5mm–3mm

- Galvanized Sheet: 0.5mm–3mm

2000W Power Equipment Weldable Thickness

- Stainless Steel: 0.5mm–4mm

- Aluminum Alloy: 1mm–3mm

- Carbon Steel (Iron): 0.5mm–4mm

- Galvanized Sheet: 0.5mm–4mm

3000W Power Equipment Weldable Thickness

- Stainless Steel: 0.5mm–6mm

- Aluminum Alloy: 1mm–5mm

- Carbon Steel (Iron): 0.5mm–6mm

- Galvanized Sheet: 0.5mm–6mm

Safety Signs

Safety Instructions

Safety Instructions

To prevent laser-related eye injuries, do not look directly at the laser head. It is strictly prohibited to aim the laser head at people, animals, or flammable and explosive items. As a precaution, place a fire extinguisher in the workplace.

After-Sales Service and Training

[Training and Maintenance]

Our company provides free technical training. After installation and commissioning are completed, we offer technical training and production guidance for your operators either at your company (with your company covering our personnel’s travel expenses, accommodation, and wages) or at our domestic training and maintenance center in China. The training lasts no less than 3 days, until the operators can use the equipment proficiently. The main training contents are as follows:

Basic Knowledge and Principles of Lasers:

- Structure, operation, maintenance, and care of the laser.

- Electrical principles, operation, programming, and general fault diagnosis of the CNC system.

- Laser processing techniques.

- Equipment operation and routine maintenance.

- Laser processing safety education.

[After-Sales Service]

- After equipment acceptance, the entire machine comes with a one-year quality warranty. The system includes one year of service and parts warranty. If any quality issues arise with system components during the warranty period, our well-trained service engineers will provide remote assistance and replacement services at any time.

- During the equipment warranty period, any damage or defects caused by the equipment’s inherent quality issues will be repaired or replaced free of charge by our company. However, this excludes regular consumables (such as optical lenses and cutting nozzles) and damages caused by user errors or improper operation.

- After installation, commissioning, and acceptance, our company can send a technician to your site for guidance (with travel expenses, accommodation, and wages covered by the user) to assist with any issues that may arise during the initial use of the equipment.

- Our company offers lifetime maintenance services for the products provided and is always available for routine consultation and guidance related to the equipment. Beyond the warranty period, we continue to provide extensive and cost-effective technical support and spare parts supply.

- Our company maintains a long-term reserve of highly qualified, rigorously trained operation and maintenance technicians, ready to serve customers at any time, eliminating the hassle of finding technical personnel.

- After the equipment is delivered, we establish a “User Profile Card” to track and record information related to the user’s equipment usage. Upon completion of maintenance services, we provide a report to the user detailing the cause of the fault, remedial measures, repair completion, and the date and time of restoration. This report is provided in duplicate for record-keeping.

- We commit to promptly informing users about software upgrades and providing free software upgrade services.

- Our company maintains an ample stock of spare parts and accessories to promptly provide technical and spare parts services, meeting equipment maintenance needs.

- We periodically arrange project engineers to visit user sites for free technical follow-up services.

Every inquiry marks the beginning of our collaboration.